Reliable water infrastructure is essential to ensuring smooth and uninterrupted operations. Water is a critical resource for many mining processes, and any disruptions caused by asset failures can lead to significant financial and operational setbacks. This is why it is crucial for mining companies to proactively assess and monitor their water assets.

Regular assessments and continuous monitoring of water pipelines, pumping stations, and overall network health are not just best practices—they are business imperatives. Unnoticed leaks, undetected pressure transients, or unexpected pump failures can quickly escalate into costly repairs, unplanned shutdowns, and lost productivity. A single failure can jeopardise entire operations, potentially resulting in downtime that could cost millions in lost revenue and delay critical project timelines.

So what are the key steps mining companies can take to safeguard their water assets? From pipeline condition assessments and leak detection technologies to permanent monitoring solutions for pumping stations, we will outline the strategies that not only mitigate risks but also extend the lifespan of critical infrastructure. And we can’t gloss over the importance of pressure transient monitoring, PRV installations, and other essential services that contribute to the resilience and longevity of water networks.

Whether you’re a water asset manager, reliability manager, or a senior executive, we offer valuable insights into how proactive water asset management can protect your operations, reduce costs, and enhance long-term sustainability in the mining sector.

Pipeline Condition Assessment

Pipeline condition assessment is critical for mining companies due to the essential role water plays in mining operations. Water pipelines are responsible for transporting large volumes of water for ore processing, dust suppression, and other operational needs. Any failure in this system, such as a burst or blockage, can cause significant disruptions, lead to costly repairs, and affect production timelines. Developing a regular program of pipeline assessments or permanent monitoring is crucial to ensuring the integrity of these networks and maintaining smooth operations.

A key benefit of pipeline condition assessments, using technology like p-CAT, is the ability to avoid catastrophic failures. By regularly inspecting pipelines, mining companies can detect early signs of internal and external wear, damage, air and gas pockets or blockages before they escalate into major issues. This proactive approach allows companies to schedule timely rehabilitation or replacement of critical sections of the pipeline, avoiding unscheduled shutdowns and minimising the risk of environmental damage.

Furthermore, through consistent monitoring, companies can begin to identify patterns and precursors to failure, enabling predictive maintenance strategies that can extend the life of their assets.

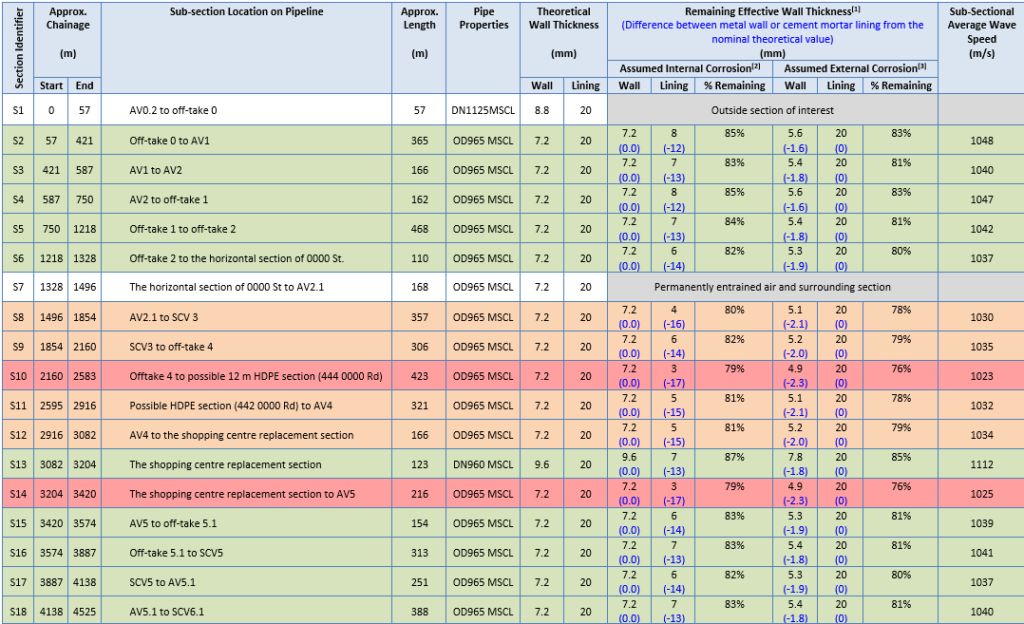

Pipeline condition assessments provide mining companies with detailed insights into several critical aspects of their water networks. For example, companies can receive pipe wall thickness and remaining strength calculations, helping them determine the durability of their infrastructure and when replacement may be necessary. Additionally, assessments can detect corrosion, cement lining losses, and sediment build-up within pipelines, which, if left unchecked, could lead to blockages and reduce flow efficiency. The location of internal blockages or debris is another key outcome of these assessments, enabling targeted cleaning or repairs to restore optimal function.

A key benefit of pipeline condition assessments is the ability to avoid catastrophic failures. By regularly inspecting pipelines, mining companies can detect early signs of internal and external wear, damage, air and gas pockets or blockages before they escalate into major issues. This proactive approach allows companies to schedule timely rehabilitation or replacement of critical sections of the pipeline, avoiding unscheduled shutdowns and minimising the risk of environmental damage.

In short, a well-planned pipeline condition assessment program provides mining companies with transparency into the health of their water networks. With this data, they can make informed decisions on maintenance, schedule repairs to avoid unexpected failures, and extend the operational life of their pipelines, ultimately safeguarding their water supply and ensuring operational continuity.

Results of a p-CAT analysis determining remaining pipeline wall thickness.

Active Leak Detection

Active leak detection is vital for mining companies that rely on vast and complex water pipeline networks. With such extensive infrastructure, undetected leaks can lead to significant water losses, operational inefficiencies, increased costs and can compromise the integrity of the impacted areas resulting in catastrophic failures. Mining operations are heavily dependent on water for various processes, and losing this critical resource can impact productivity, damage equipment, and lead to environmental concerns.

By identifying and repairing leaks early, mining companies can significantly reduce the strain on their resources, extending the operational life of pipelines and ensuring water is used efficiently. Pipeline leaks not only waste water but also require additional energy to maintain water flow and pressure, driving up operational costs and stressing the entire system. Active leak detection programs offer mining companies an effective way to prevent these issues by pinpointing and resolving problems early on.

Acoustic leak detection is one of the most effective methods available, allowing companies to detect leaks that may be hidden underground or in remote areas of the site. This technique uses sound waves to identify the precise location of a leak, enabling quick and targeted repairs. Correlation and analysis tools further refine the detection process by measuring the time it takes for sound to travel between sensors, accurately identifying leak locations across large distances.

Ground surveys play an essential role by providing a detailed assessment of pipeline integrity and potential vulnerabilities. Water audits and balance studies help mining companies understand their overall water usage, identify discrepancies, and optimise water management. These programs ensure that water losses are minimised, helping the company meet sustainability goals while reducing costs.

Permanent and temporary acoustic logging systems provide ongoing monitoring, giving mining companies the flexibility to continuously assess pipeline conditions or conduct short-term studies to address immediate concerns. The combination of these technologies ensures comprehensive leak detection, safeguarding resources, reducing downtime, and maintaining operational efficiency.

Detect water leaks no matter how remote their location.

Permanent Network Monitoring

Permanent monitoring of water pipeline networks is vital for mining companies to maintain operational efficiency, prevent costly disruptions, and manage resources sustainably. The complexities of water usage in mining—ranging from tailings dam management to dust suppression and ore processing—require a robust understanding of network performance. Implementing permanent monitoring systems gives mining companies the ability to proactively intervene before minor issues escalate into significant failures.

One critical area where mining operations benefit from permanent monitoring is energy efficiency in pumping systems. Utilising technologies like Riventa, companies can continuously track the performance of their pumps, identifying inefficiencies and optimising energy consumption. Since pumping systems are a major cost driver, improving energy efficiency can deliver substantial financial savings, while also reducing the carbon footprint of operations. Importantly, permanent monitoring is also highly effective in reducing the incidence of breakdowns and prolonging the economic life of their pumps.

By leveraging real-time data and analytics, companies can significantly extend the economic life of their equipment, reduce the incidence of breakdowns, and slash maintenance costs.

Transient pressure management is another key advantage. Mining companies must contend with pressure transients—sudden changes in water pressure that can cause pipe fatigue, bursts, or leaks. By monitoring these transient activities, companies gain real-time insights into stress points in their pipeline networks. This allows them to adopt preventive measures, such as installing surge protection devices, change the pumping operation, and review automatic operations to mitigate these damaging pressure spikes.

The installation and monitoring of Pressure Reducing Valves (PRVs) play an essential role in controlling water pressure across the network. Properly monitored PRVs ensure that pressure is regulated to optimal levels, preventing over-pressurisation that could strain pipelines and lead to system failures.

Incorporating valve exercising and monitoring programs further bolsters network health. Valves are crucial components, yet they often remain idle for long periods. Regular exercising prevents seizing or malfunctioning, ensuring that they can be operated when needed for routine maintenance or in an emergency.

Finally, mining companies can gain significant insights through acoustic, pressure, and flow change data analysis. These datasets allow for the detection of leaks and inefficiencies that would otherwise go unnoticed. Early detection of anomalies enables timely repairs, extending the lifespan of pipelines and reducing water losses.

By investing in permanent monitoring solutions, mining companies not only ensure the integrity and longevity of their water networks but also drive operational efficiency, reduce costs, and safeguard critical resources.

Incorporating cutting-edge technology and a proactive approach to water asset management empowers mining companies to minimise costly surprises, extend asset lifespan, and ensure operational resilience. By investing in comprehensive monitoring and assessment strategies, companies can safeguard their resources and secure a more sustainable, efficient future.