Introduction

SunWater is Queensland’s largest regional bulk water service provider. Sunwater is responsible for the operation and maintenance of 19 dams and a network of weirs, channels and pump stations. They service over 1,150 kilometres of pipelines for agricultural, community and industrial customers.

The Challenge

As part of SunWater’s water main maintenance program, a condition assessment of pipeline integrity was required to confirm the current status of the pipeline in terms of structural integrity, stability, rate of deterioration etc.

The objectives of condition assessment can vary from operations and maintenance requirements, increasing capacity, improving efficiency to compliance, risk assessment and funding for maintenance or repairs. To ensure reliable operation, negate the high cost of shutting down the pipeline, Sunwater required a non-invasive inspection to ensure no loss of production and no risk of water contamination.

The Assessment

Detection Services patented p-CATTM is a non-invasive, non-destructive technology for performing pipe condition assessment and to date, the most comprehensive and advanced solution for long distance pipelines. p-CATTM can determine remaining wall thicknesses over long sections (many kilometres) of pipeline as well as detect and locate defects such as air and gas pockets, internal blockages and restrictions, unknown connections, pipe material changes and cement matric loss from AC pipes.

p-CATTM works by analysing the partial reflection of a small, controlled transient signal that is injected into the pipeline. The signal is monitored and recorded by sensors that are temporarily installed on existing pipe fittings. The transient wave experiences partial reflection when it encounters any change in pipeline structure, including both known features of the system as well as other issues related to pipe deterioration.

A comprehensive desktop study and site inspection were undertaken prior to p-CATTM testing in order to develop a tailored test plan for the pipeline. The established test plan enabled high quality results to be collected within the allocated time frame with minimal disturbance to the system operation.

The Solution

p-CATTM condition assessment was applied to a 16-inch (400mm) MSCL water main. During testing, p-CATTM equipment, which includes a pressure transducer, a data acquisition stations and a transient generator, were attached to existing pipeline fittings – primarily air valves. A small, carefully controlled pressure transient was introduced into the pipeline at several locations along the assessed section, and the resultant data captured and collated.

Testing was conducted at nine locations within the two days allocated for field works. The original scope of work was to assess 5 km of pipeline. However, Detection Services were able to collect sufficient data for the analysis of 14 km of pipeline within the two days.

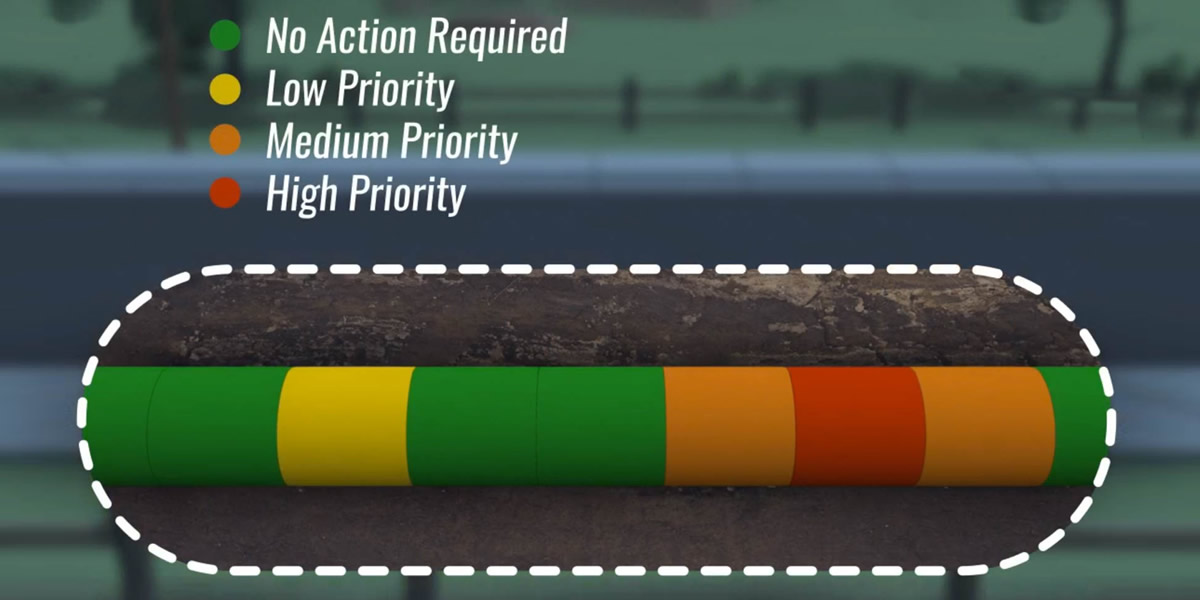

The collected data was subsequently analysed using an advanced and patented algorithmic method based on the speed of the transient signal. p-CATTM analysis has determined the remaining wall thicknesses for 37 sub-sections of different deterioration conditions over this 14 km section and has also identified and located several anomalies including a potential service connection not known to SunWater and a deteriorated section.

Another significant finding was the presence of high air content, which is potentially the main cause of deterioration of this section. The locations of known pipeline features, including air valves, scour valves and an opened off-take were also identified during the analysis.

During p-CATTM testing, Detection Services also identified potential issues related to the operation of the pump station. The field observations regarding the pump cycle times and transients generated during pump start and stop sequences, together with potential consequences and recommendations were also provided to SunWater.

The approach adopted for SunWater showcases how Detection Service’s innovative

technology and solutions allow customers to optimise resources and maximise the

value of their assets across their lifecycle.