The integrity of pipelines is paramount for water utilities, mining companies and councils around the globe. The ability to accurately undertake pipeline condition assessments without invasive measures is a game-changer, and that’s where p-CAT steps in as a revolutionary and disruptive solution.

Designed and developed in Australia, p-CAT (short for Pipeline Condition Assessment Technology) sets itself apart as a non-invasive and non-destructive method for evaluating the health of pipelines. Unlike traditional methods that often require excavation or extensive dismantling, p-CAT operates by analysing the partial reflection of a controlled transient signal injected into the pipeline. This signal is then monitored and recorded by sensors temporarily installed on existing pipe fittings.

But what truly distinguishes p-CAT from other tonal pipeline assessment and acoustics technologies on the market?

p-CAT has been tested and validated by multiple independent consultants and water authorities in Australia and the US and approved by the Intelligent Water Network (IWN).

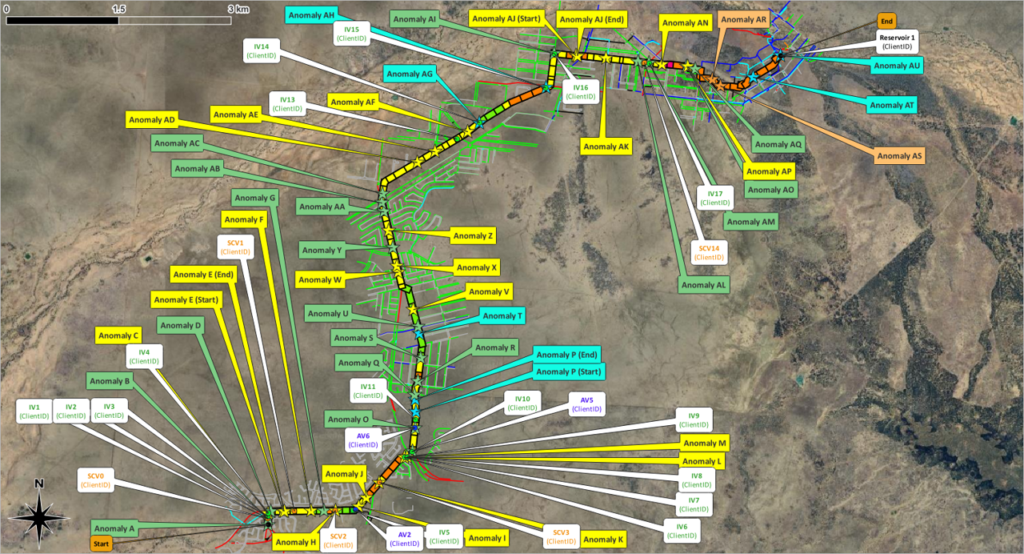

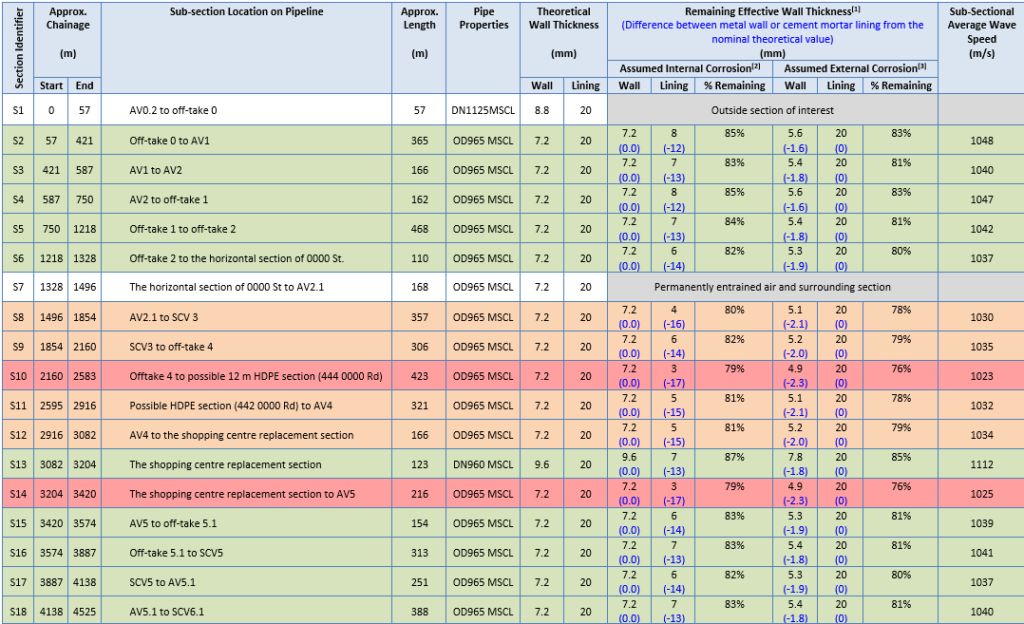

Comprehensive Analysis: p-CAT offers unparalleled insight into pipeline health by providing a comprehensive analysis of various parameters. It not only determines remaining wall thicknesses over long sections of the pipeline but also detects and locates defects such as air and gas pockets, internal blockages, unknown connections, pipe material changes, and even cement matrix loss from metallic, concrete, and AC pipes. This holistic approach ensures that no potential issue goes unnoticed, allowing for proactive maintenance and repair strategies.

“One of the most significant advantages of p-CAT is its non-invasive nature. Unlike techniques that require excavation or intrusive inspections, p-CAT can assess pipeline condition without disrupting operations or causing damage to surrounding infrastructure. This not only reduces downtime and associated costs but also enhances safety for personnel and the community.”

Precision and Accuracy: By analysing the partial reflection of the transient signal, p-CAT achieves a level of precision and accuracy that surpasses traditional assessment methods. The technology can pinpoint the exact location and nature of defects within the pipeline, enabling targeted interventions and minimising unnecessary repairs or replacements. This not only saves time and resources but also reduces the risk of service disruptions and environmental damage associated with pipeline failures.

Non-Invasive Nature: One of the most significant advantages of p-CAT is its non-invasive nature. Unlike techniques that require excavation or intrusive inspections, p-CAT can assess pipeline condition without disrupting operations or causing damage to surrounding infrastructure. This not only reduces downtime and associated costs but also enhances safety for personnel and the community.

Cost-Effectiveness: By accurately identifying defects and their precise locations, p-CAT optimises maintenance and repair efforts, resulting in significant cost savings for water utilities and councils. Instead of undertaking wholesale replacements or extensive repairs, asset managers can focus their resources on addressing specific areas of concern, maximising the lifespan of existing infrastructure, and optimising budget allocation.

Applicability to Various Pipeline Types: Whether it’s potable water, raw sewage, or wastewater pipelines, p-CAT proves to be a versatile solution suitable for a wide range of fluid-filled pipelines. Its adaptability makes it an invaluable tool for asset managers tasked with overseeing diverse infrastructure networks.

p-CAT represents a paradigm shift in pipeline condition assessment, offering unmatched accuracy, efficiency, and cost-effectiveness. Its ability to provide comprehensive insights into pipeline health while remaining non-invasive makes it a preferred choice for asset management and civil engineers in water utilities and councils worldwide. Embracing p-CAT not only enhances the resilience and longevity of pipeline networks but also reinforces the commitment to sustainable infrastructure management for generations to come.

At the recent Pipe Industries Guild 2024 Technical Awards, Utilities Panel Chair, Jon Drake (CEng MICE), Senior Civil Engineer at United Utilities highlighted the significance of p-CAT™, stating, “p-CAT™ was the most significant leap forward in pipe wall condition assessment in the last twenty years with its ability to identify hotspots of deterioration over long lengths of pipe.”

With projects spanning Australia, New Zealand, Singapore, Asia, UK, Europe, China, USA and the middle East, chat with us today about how p-CAT can assist you in identifying assets in need of rehabilitation or replacement.