Trenchless technology is critical in checking already-buried pipes and keeping them operating and properly maintained.

Detection Services is changing the game when it comes to assessing the condition of pipelines worldwide using Australian-designed and developed technology. With projects across Australasia, North America, Europe, the Middle East and Asia, the company specialises in multi-discipline pipe solutions and state-of-the-art technologies.

Detection Services is committed to extending the life of pipeline assets through its innovative solutions, including pipeline inspection and assessment, monitoring, maintenance, data collection, and analysis.

Penny Wrightson is the project manager and senior analyst at Detection Services. She has nearly 10 years’ experience with the company, starting just after graduating from university.

“A friend of mine was working on a significant project called p-CAT with Detection Services,” she said. “At the time, the University of Adelaide and Detection Services were highly interconnected, so when a position opened up at Detection Services, she pointed me to it. I’ve been there ever since.”

What’s p-CAT?

The deteriorating state of water infrastructure can lead to pipeline failures, emergency repairs, reduced reliability, and increased financial costs. This is all before considering the environmental and community impact and the loss of a social license.

This is why Detection Services focuses on applying innovative pipeline technologies as expectations surrounding critical infrastructure continue to grow. Its condition assessment technologies can translate data into actionable results, enabling utilities to evaluate risk and prioritise asset rehabilitation or replacement. The efficient allocation of resources can optimise pipeline reliability while improving outcomes for local governments and water utilities.

Of course, achieving this requires the right technology. Detection Services offers a technique called p-CAT, a non-invasive and non-destructive technology designed for pipe condition assessment. It can determine wall thickness over long pipeline sections while also detecting and locating defects such as air pockets, internal blockages, unknown connections, and changes in pipe material.

How does it work?

p-CAT analyses the partial reflection of a small, controlled transient signal injected into the pipeline. Sensors temporarily installed on exiting pipe fittings monitor and record this reflection. By picking up the partial reflections when encountering changes in the pipeline structure, Detection Services can separate known changes from unknown changes.

“p-CAT uses a water transient signal in a similar way that people use radar,” Wrightson said. “We send a small and controlled transient signal down the pipe and collect all the reflections that come back. Our technology can detect all the changes that we typically find in a pipe. That includes lining loss, material loss and changes in pipeline configuration. All that information is collected by our instruments and compared against existing maps and any other provided information.”

Water utilities and local governments can determine what might be happening in any specific location by comparing the information against maps.

“For example, we can work out if a wall is thinner in a particular part,” she said. “If there’s a sharp change in the signal, we can see if there might be a blockage or an air pocket. It’s an opportunity to look at the maps to see if there is a logical explanation for what is causing this change.”

Effectiveness of p-CAT

One significant benefit of the p-CAT system is its ability to be implemented across a large pipe network. Wrightson explained that the teams typically operate over two-kilometre sections. Depending on conditions, they can cover up to 12 km or more per day.

“In reality, we can detect the smallest of defects and remaining wall thickness across hundreds of kilometres of pipe network,” said Wrightson. “Our pinpoint methods yield valuable information which allows asset owners to focus their attention to defective sub-sections of well under 10 metres in length. The p-CAT method is less risky and more efficient than more invasive techniques.”

Reflecting on previous challenges faced by Detection Services, Wrightson described a project in New Zealand. The project involved a pipe that was believed to require an additional pump due to significant pressure and capacity constraints.

One significant benefit of the p-CAT system is its ability to be implemented across a large pipe network. Wrightson explained that the teams typically operate over two-kilometre sections. Depending on conditions, they can cover up to 12 km or more per day.

“We conducted tests and analysed the situation over Christmas,” said Wrightson. “We discovered that there was no need for a new pump. In reality, there was a half-closed valve that had become stuck in the middle of the pipe. Installing a second pump would have essentially meant pumping against a closed valve. This example demonstrates how we can perform remedial work to prevent further damage to the network system. It’s a quick way to identify significant issues and evaluate the overall system.”

Designed for people

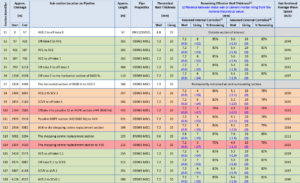

It’s not just the technology that is simple. The associated software platforms are designed for end-users to understand the information they receive. Properly analysing the data comes in the form of a colour-coded priority list and a geographic information system (GIS) map.

“We provide the data in these ways, so it is easy for our end-users to understand and implement,” Wrightson said. “We work with our clients to determine their priorities and build them into the system. We can consider the impact of various issues, including the number of affected customers, the damage that could be done, wall thickness, and any other qualifiers they want.”

That sort of customised understanding of individual clients has helped Detection Services rise to the top of the hill regarding remote pipeline condition assessment. By drilling down to a specific address, it is providing better value for its customers and any potentially affected residents.

The improved value also highlights the cost savings on offer. One project in Queensland could have cost the local council more than $30 million to replace the pipe that they considered to be in poor condition, but with p-CAT, the ultimate refurbishment cost came to less than half a million dollars. Technology like this continues to drive innovation in the trenchless technology space.

“We’re helping them save a lot of money. Generally speaking, it’s cheaper per kilometre to do a big stretch of pipe rather than a small one,” Wrightson said. “If you consider it bulk buying, we can do most distances in a single day.”

Get in touch with out p-CAT team today to discuss your pipeline condition assessment needs.

Inside Water July 2024