Pipers® is an in-line inspection technology specifically designed to address the challenges faced by the water, wastewater, bulk water, and other pipeline marketplaces. These baseball sized multi-sensor devices are free-floating, making them a highly versatile solution for virtually any pipeline. Pipers® are an amazing solution that can be used to effectively address a wide array of pipeline-related problems, including an assessment of the pipeline wall condition, mapping deposits, localizing leaks and air pockets, and even illegal hot tapping.

The versatility of Pipers® extends across various pipeline scenarios, including treated water, raw water or wastewater mains, lines that cannot be taken out of service, challenging-to-inspect (Non-piggable) pipelines, diverse pipe diameters from four inches and above, and various pipeline materials such as CI, DI, CS, AC, RCP, PCCP, PVC. Furthermore, they are suitable for long pipeline lengths and deeply trenched pipelines.

Key Features and Benefits of Pipers® include:

100% Uptime: Ensuring uninterrupted pipeline monitoring and data collection.

Rich Datasets Library: Providing extensive historical data for unparalleled analysis.

Non-revenue Water Detection: Identifying leak locations to minimise water loss.

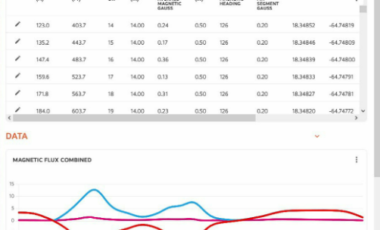

Multi-Sensor Surveys: Offering comprehensive data on leaks, air pockets, pressure, buildup, and wall conditions in a single run.

Gas Line Inspection: Facilitated through a dedicated cleaning pig attachment and deployment.

Operational Versatility: Designed for use under live operational conditions, ensuring minimal disruption.

Utilisation of Historical Data: Leveraging past data for unprecedented analysis and insight.

For more information, please contact us on 1300 722 835 or through our contact page.