In the pursuit of optimising infrastructure management and ensuring the reliability of its water supply network, a leading water utility in Australia had initiated a comprehensive pipeline rehabilitation and replacement project on what it described as “one of the most critical assets in their entire water network.” This approach, while straightforward, often leads to unnecessary expenditures and disruptions, as entire pipeline segments are replaced regardless of their actual condition.

To address these inefficiencies, the utility has adopted an innovative condition assessment program that allows for a much more targeted and strategic approach to pipeline replacement and rehabilitation, potentially saving tens of millions of dollars annually.

This case study focuses on the condition assessment of this section of water pipeline, a critical component of the utility’s network. Detection Services was commissioned to conduct p-CAT™ Nexus testing and provide detailed findings regarding the pipeline’s condition. The primary objectives of the assessment were to evaluate the pipeline’s condition and identify features and anomalies such as blockages, air pockets, and wall thickness deterioration.

“It is one of the most critical assets in the utilities water network. There were question marks over the condition of this pipeline based on its history, as well as another pipe close by.” Utility Project Engineer

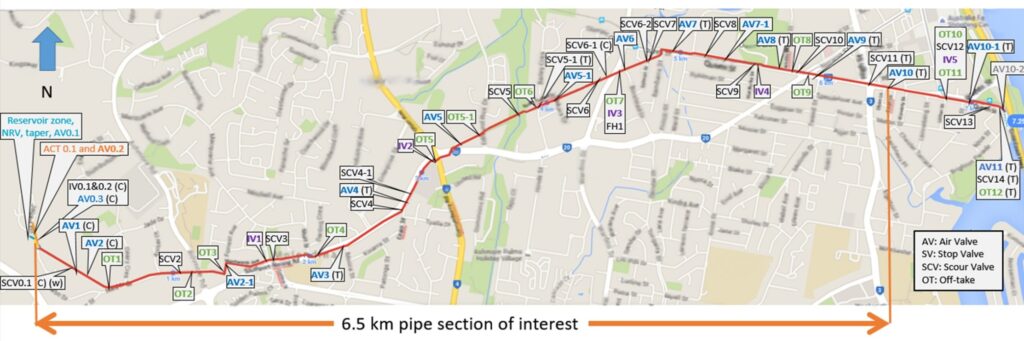

The pipeline in question, constructed in two stages in 1982 and 1983, spans approximately 6.5 kilometers. Stage 1, completed in 1982, while Stage 2 was completed in 1983. The pipeline is predominantly composed of OD965 Mild Steel Cement Lined (MSCL) pipes, with several short sections of DN960 MSCL replacements.

Given its critical role in the water network, there were significant concerns regarding the pipeline’s construction and materials. Notably, the pipeline had been stored on the dockside for an extended period before installation, raising questions about its integrity. Furthermore, there was fairly minimal failure history, primarily related to fittings and rubber ring joints, which compounded the concerns about the pipeline’s overall condition.

Based on historical information and the potential risks associated with the pipeline, the initial plan was to replace the entire section, with an estimated cost between $30 – $40 million. This plan was included in the capital forecast, reflecting the utility’s commitment to ensuring the reliability of its infrastructure. However, there was a recognised need for a better understanding of the business risks associated with potential pipeline failures, which prompted the utility to seek alternative solutions through Detection Services.

The Outcome

p-CAT™ Nexus uses two main techniques for interpreting the transient pressure wave tests results:

- Sub-Section Partitioned Wave Speed Analysis™ for assessment of the level of deterioration of the pipe wall in a sub-section, and

- Signal Analysis for detection of known features and significant anomalies such as air pockets and blockages.

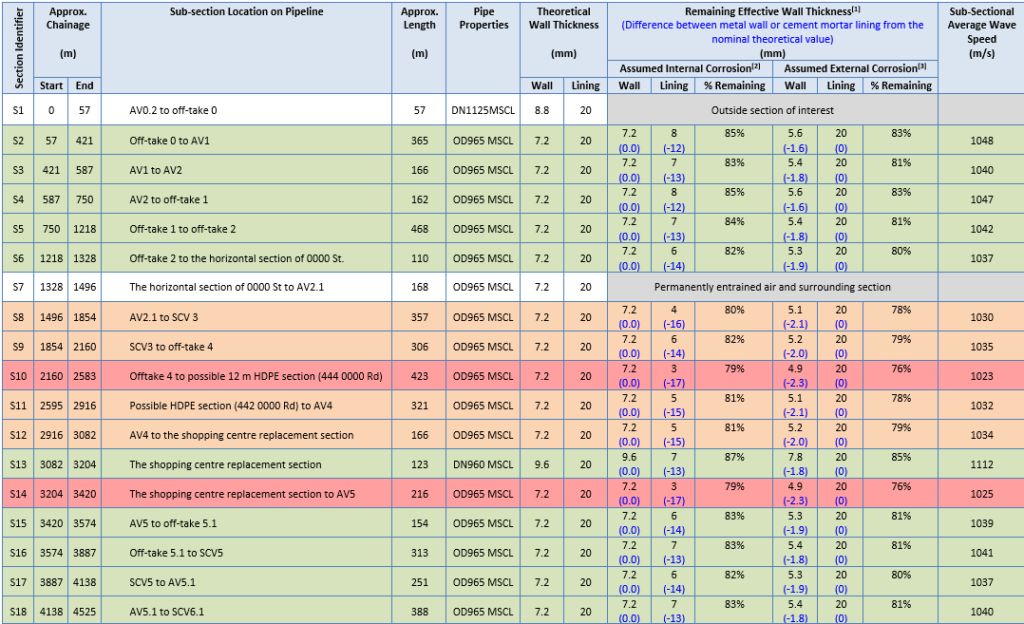

The analysis undertaken to determine the pipeline wall condition was based on the assumption that the pipeline was constructed with the below specifications:

- Outside diameter of 965 mm (as indicated on the as-constructed drawings)

- Wall thickness of 6 mm (considering the wall thickness as stated in the as-constructed drawings and a manufacturer tolerance as per ISO559:1991)

- Cement mortar lining of 16 mm (considering a manufacturer tolerance in compliance with AS1281:1993)

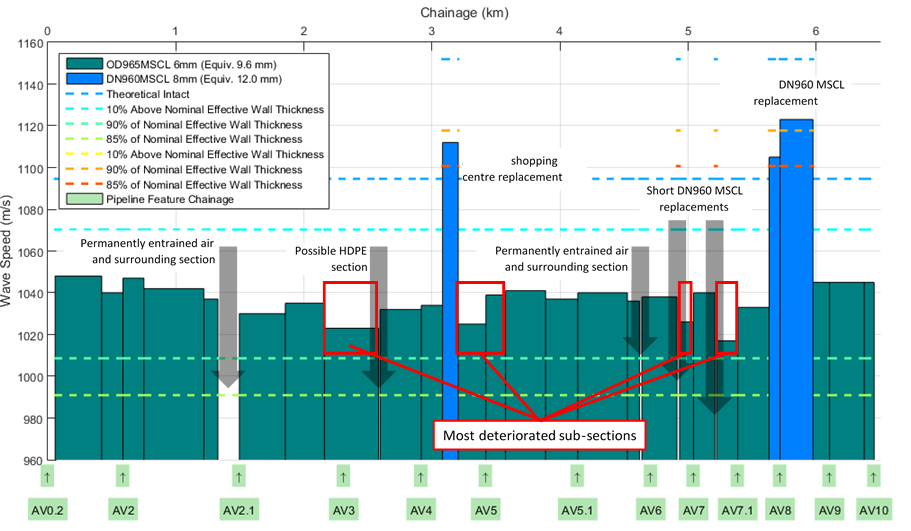

The following pipeline wall condition was identified during the p-CAT™ Nexus analysis:

- 12.5% of the total pipeline length has a remaining wall thickness of 74 to 76%.

- 23.4% of the total pipeline length has a remaining wall thickness of between 77 to 79%.

- The rest of the pipeline (59.9% of the total length) has a remaining wall thickness of 80 to 89%.

The following known features and anomalies, and their resulting recommended actions were also identified during the signal analysis:

- Two HIGH priority anomalies representing the presence of large pockets of permanently entrained air.

Three medium priority anomalies representing:

- An open off-take (OT4) which was presumed closed,

- A section of replacement pipe or a possible air pocket,

- And a pocket of permanently entrained air at an air valve (AV5.1).

Seven low priority anomalies representing known features including:

- A large open off-take,

- Four replacement sections of pipe, and

- The branches on two sealed off-takes

“The cost replacing the pipeline was estimated at 30 to 40 million dollars and it was in the capital program. We had every intention to go ahead with that.” Utility Project Engineer

The condition assessment conducted by Detection Services provided invaluable insights, ultimately deferring the planned capital project. This proactive approach has allowed the utility to implement a more strategic condition assessment program, leveraging innovative technologies and methodologies to maintain and enhance their water network more efficiently. This case study details the findings and impact of the p-CAT™ Nexus testing on the particular Water Pipeline, underscoring the importance of targeted infrastructure management in modern utility operations.

Importantly, all of the detailed information was acquired without taking the asset out of service and without carrying out any invasive techniques.

If you would like to learn more about our pipeline condition assessment solutions, please get in touch with us here.