Water pipelines play a crucial role in sustaining mining operations, essential for extracting and processing minerals like coal, gold, copper, silver, lead, zinc, cobalt, and lithium. Pipeline failures can severely impact both operational efficiency and financial stability. We dig into the repercussions of water pipeline failures for mining organisations and highlight the critical need for proactive maintenance, robust infrastructure investments, and advanced condition assessment technologies like p-CAT™ and INGU’s Pipers®.

Operational Consequences

More often than not water pipeline failures result in an immediate halt to mining operations. The sudden cessation of water supply forces machinery to stop, interrupts processing, and can create significant safety hazards. This operational chain reaction not only delays production but can also compromise the safety of the workforce.

The disruption in water supply affects the various stages of mining, from extraction to processing. This leads to logistical challenges, including the need for emergency response coordination, workforce management, and reallocation of resources. The interruption can cause a ripple effect, throwing a spanner into the entire supply chain and delaying project timelines.

Financial Costs

The financial losses due to halted operations are substantial. Every day of downtime can result in significant revenue loss, potentially amounting to tens of millions of dollars. If the downtime extends over several days or weeks, the long-term financial impact can be devastating, affecting the company’s profitability and market position.

The direct costs of repairing a failed pipeline include materials, labor, and equipment. Additionally, expedited services or overtime work to minimise downtime can further inflate these expenses. Repairing a pipeline is not just about fixing the immediate problem; it often requires comprehensive inspections and additional preventive measures to avoid future failures. An Australian mining company recently estimated the cost of replacing a 50km-60km stretch of their pipeline was in excess $150 million. This highlights the substantial cost of replacement and how isolating and identifying areas with a likelihood of failure is a much better strategy.

Pipeline failures can lead to penalties or fines from regulatory bodies due to environmental damage caused by uncontrolled water flow, contamination, and erosion. Moreover, the potential loss of contracts or delays in project timelines has the risk of negatively impacting on the company’s financial standing and reputation.

Broader Consequences and Ramifications

Uncontrolled water flow from pipeline failures can cause significant environmental damage, including contamination and erosion. The long-term ecological consequences require extensive remediation efforts, which are both time-consuming and costly. These environmental impacts can also lead to stricter regulatory scrutiny and compliance issues.

The impact of pipeline failures extends beyond immediate operational and financial costs. Such incidents can tarnish the company’s reputation within industry and among stakeholders. Examples of past incidents have shown that public perception can be significantly affected, leading to a loss of trust and potential business opportunities.

Adhering to regulatory requirements and industry standards is crucial for mining operations. Pipeline failures can result in legal ramifications and increased regulatory scrutiny. Implementing regular maintenance schedules and adhering to compliance standards are essential to prevent such incidents and ensure the smooth operation of mining activities.

What are the Solutions?

As we have outlined, water pipeline failures in mining operations have far-reaching consequences. Preventative maintenance and investment in robust pipeline infrastructure are essential to safeguarding operations and minimising risks. Mining executives and engineers can prioritise pipeline integrity and leverage advanced detection and monitoring technologies, such as p-CAT™ and INGU Pipers®, to ensure the longevity and reliability of their water pipelines.

“The detailed reports generated by p-CAT™ equip maintenance teams with the data needed to prioritise repair and replacement activities. Understanding the exact condition of the pipeline helps in scheduling maintenance before minor issues escalate into major failures, thereby preventing costly downtimes and ensuring continuous operations.”

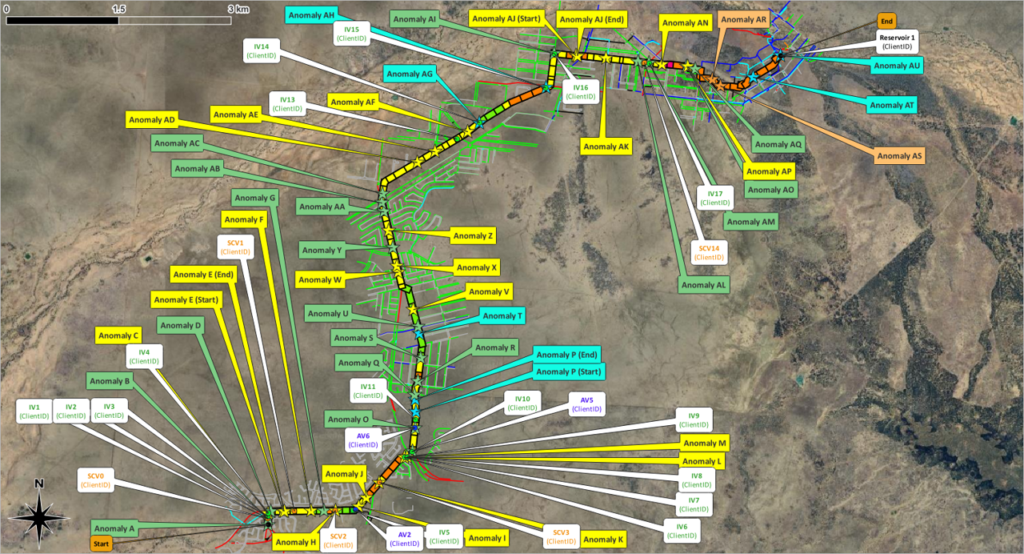

A p-CAT™ condition assessment provides a comprehensive analysis of pipeline integrity, enabling precise and informed decision-making for preventive maintenance.

By employing p-CAT™, mining companies receive detailed reports on various critical parameters. These include the degree of pipeline deterioration, allowing for early detection of potential weak points. The solution meticulously measures wall thickness, identifying areas that may be thinning and prone to leaks or bursts. It also detects air and gas pockets, which can cause pressure imbalances and reduce the efficiency of fluid transport.

The detailed reports generated by p-CAT™ equip maintenance teams with the data needed to prioritise repair and replacement activities. Understanding the exact condition of the pipeline helps in scheduling maintenance before minor issues escalate into major failures, thereby preventing costly downtimes and ensuring continuous operations.

Integrating p-CAT™ assessments into a preventive maintenance strategy ensures that maintenance efforts are proactive rather than reactive. By addressing issues identified in the detailed reports, mining companies can extend the lifespan of their pipelines, enhance safety, reduce the risk of environmental contamination, and maintain optimal operational efficiency. This strategic approach ultimately results in significant cost savings and improved reliability of mining operations.

The significance of Pipers® lies not just in their advanced capabilities but also in their versatility. Suitable for all pipelines regardless of diameter or material, they can operate while the pipeline is in service—a critical feature for minimising disruption. Designed specifically for the challenges encountered in water, wastewater, bulk water, and other pipeline sectors, Pipers® offer an unprecedented level of adaptability, catering to diverse pipeline configurations with ease.

But what sets Pipers® apart is not just their ability to identify issues; it’s their comprehensive approach to pipeline management. Through multi-sensor surveys, they provide a holistic view of pipeline conditions, covering everything from leaks and air pockets to pressure and wall conditions – all in a single run. This comprehensive data empowers asset managers to prioritise maintenance efforts effectively, ensuring pipelines operate safely and reliably.

By addressing the critical aspects of pipeline failure, mining industry professionals can mitigate risks, ensure the continuity of their operations, and maintain a strong market position. It is imperative to assess current pipeline maintenance strategies, enhance pipeline integrity, and invest in advanced technologies to reduce the risk of failures.

Chat to us today about our condition assessment programs and how they can provide clarity around the condition of your water assets.